Article At A Glance

- Evolving from manual to computer-controlled processes, machining techniques have advanced with the growing demand for high-performance vehicles.

- Precision engineering is essential to meet consumer expectations and strict industry standards in producing intricate geometries.

- Recent innovations in machining technology include CNC, additive manufacturing, hybrid machining, and multi-axis machining.

As the automotive industry advances, precision and performance in manufacturing are essential for creating high-quality vehicles. Innovations in machining technologies are driving this evolution, enabling manufacturers to produce high-performance components with exceptional accuracy, durability, and efficiency. These advancements are crucial in meeting the growing demand for sustainable, eco-friendly transportation solutions.

An Overview of Machining in Automotive Manufacturing

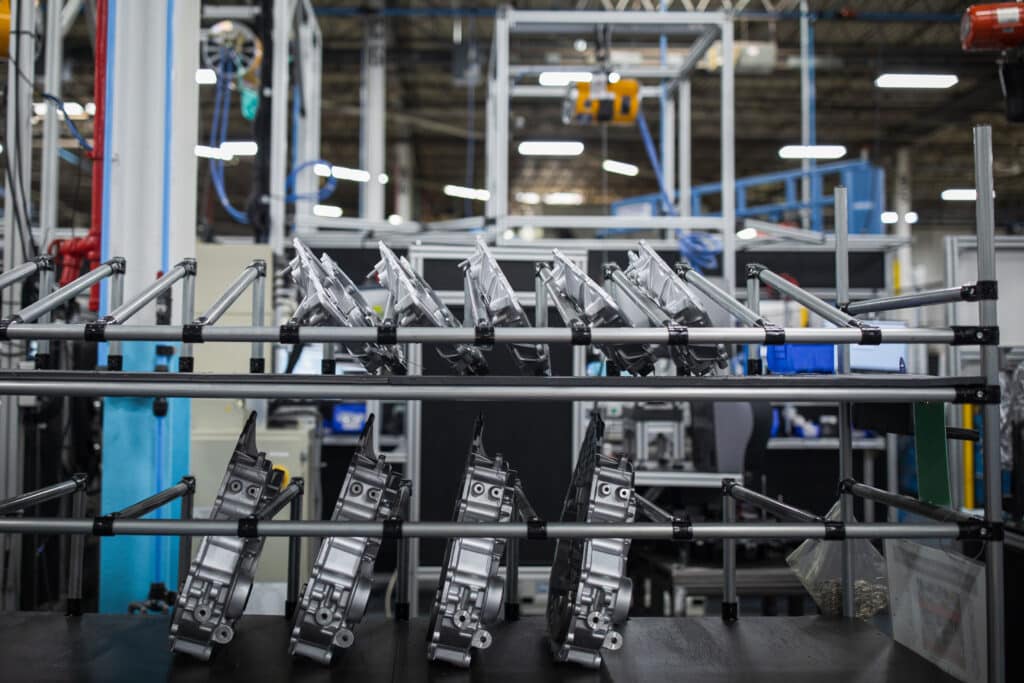

Machining is a critical process in the automotive industry. It is a key method for manufacturing automotive components with high precision and accuracy. It involves various subtractive manufacturing techniques, such as removing material from a workpiece to achieve desired shapes and specifications. In automotive production, machining is essential for creating intricate designs and components that meet strict performance and safety standards.

Over time, machining techniques have evolved significantly, transitioning from traditional manual processes to advanced computer-controlled systems. These advancements have enabled manufacturers to produce high-quality components with tighter tolerances, enhancing vehicle performance and reliability.

The Growing Demand for High-Performance Automotive Components

The rise of high-performance and luxury vehicle markets has driven the automotive sector to prioritize precision engineering and advanced manufacturing techniques. Consumers today demand vehicles that offer superior performance, exceptional fuel efficiency, and safety features. This increasing market demand has pressured automotive manufacturers to innovate continuously, pushing the boundaries of what is possible in automotive design and functionality.

Precision engineering is paramount in producing high-performance automotive components, where even minor deviations can affect overall vehicle performance. Creating intricate geometries that accommodate the latest automotive technologies is essential for meeting consumer expectations and complying with stringent industry standards.

Key Innovations in Machining Technology

Recent innovations in machining technology have transformed the landscape of automotive manufacturing. Computer numerical control (CNC) has emerged as a leading technique for automating machining processes. CNC machines provide unparalleled precision and repeatability, allowing manufacturers to produce complex geometries with tight tolerances.

Additional Read: The Impact of Advanced CNC Machining in Automotive Component Remanufacturing

Additive manufacturing and hybrid machining are also gaining traction in the automotive sector. While traditional machining is subtractive, additive manufacturing builds components layer by layer, offering greater design flexibility and material efficiency. Hybrid machining combines both techniques, allowing manufacturers to create intricate designs while maintaining production efficiency. This approach is particularly beneficial for producing components like engine parts and turbochargers that require precision and complex geometries.

Additional Read: Advanced Electrification Solutions For EV & Hybrid Vehicles

Multi-axis machining is another critical innovation that facilitates the production of complex components. Allowing tools to move in multiple directions, multi-axis machines can create intricate designs previously difficult or impossible to achieve with traditional machining methods. This capability is especially valuable in producing high-performance automotive components, where intricate designs are essential.

Materials Used in High-Performance Automotive Machining

The choice of materials is vital in high-performance automotive machining. Manufacturers increasingly rely on lightweight materials such as aluminum, titanium, and carbon fiber to enhance vehicle performance while reducing weight. These materials offer a combination of strength and reduced mass, contributing to improved fuel efficiency and handling.

High-strength alloys and composites are also integral to automotive applications, providing the durability and performance required for modern vehicles. However, machining these advanced materials presents unique challenges. For instance, titanium and certain aluminum alloys can be difficult to machine due to their hardness and propensity for tool wear. Innovations in cutting tools and machining techniques are essential to address these material challenges while ensuring high-quality production.

Precision Machining for Performance-Enhancing Components

Precision machining is vital in producing performance-enhancing components such as engine blocks, turbochargers, and transmissions. The intricate designs required for these parts necessitate advanced machining techniques to ensure optimal performance and durability.

By employing modern machining technologies, manufacturers can enhance the durability and performance of automotive components. For instance, precision machining can significantly improve the fit and finish of engine components, leading to better overall vehicle performance and longevity. Using advanced materials in conjunction with precision machining also ensures that components can withstand the demanding conditions in high-performance automotive applications.

Benefits of Modern Machining Techniques

The adoption of modern machining techniques yields numerous benefits for automotive manufacturers. Improved efficiency and accuracy in machining processes reduce production costs while enhancing product quality. Streamlining production processes enables manufacturers to achieve faster production timelines and respond swiftly to changing market demands.

Modern machining techniques contribute to reduced waste and material costs. Manufacturers can optimize material usage with greater precision and automation, leading to a more sustainable production process. This focus on efficiency aligns with the automotive industry’s broader goals of minimizing environmental impact while meeting consumer expectations for high-quality vehicles.

Challenges in Machining for High-Performance Applications

Despite the advancements in machining technology, several challenges remain in producing high-performance automotive components. One of the primary challenges is addressing material hardness and tool wear. Many advanced materials in automotive manufacturing can cause rapid wear on cutting tools, necessitating ongoing investment in new tooling and technology.

Quality control is another critical factor in machining for high-performance applications. Maintaining tight tolerances throughout the production process is essential to ensure that components meet rigorous standards. Manufacturers must implement robust quality assurance processes to monitor machining operations and address any deviations from specifications.

The Future of Machining in the Automotive Industry

Advancements in machining technology are transforming automotive manufacturing by enabling the production of high-performance components with remarkable precision. Techniques like multi-axis CNC machining and additive manufacturing allow for intricate geometries and lightweight designs using advanced materials like titanium and carbon fiber. These innovations improve fuel efficiency, reduce emissions, and support the industry’s push for sustainable solutions.

Rising demand for high-performance and eco-friendly vehicles continues to drive progress. Flexible systems now support customization while maintaining efficiency, and advancements in tools help process tough materials like high-strength alloys. These technologies ensure durable, precise components while minimizing waste, solidifying the industry’s focus on sustainability and high-quality performance.

Driving the Future of Automotive Manufacturing

Innovations in machining technology are revolutionizing the automotive industry, enabling manufacturers to produce high-performance components that meet the demands of modern vehicles. These innovations, from CNC advancements to lightweight materials, enhance precision, efficiency, and overall vehicle performance. As the automotive sector continues to evolve, integrating advanced machining techniques will play a vital role in shaping the future of automotive manufacturing. For more information about cutting-edge machining solutions, contact Dynamic Manufacturing in Hillside, IL, at (708) 343-8753.