Reducing Waste and Environmental Impact in the Automotive Industry

In an era where sustainability is crucial, remanufacturing is becoming key in the automotive industry. Dynamic Manufacturing leads this sustainable wave by reducing waste and minimizing environmental impact with innovative processes. This blog explores how remanufacturing reshapes the industry, highlighting its importance for OEMs, environmental benefits, and role in promoting sustainable vehicle production.

Remanufacturing and Sustainability in the Automotive Industry

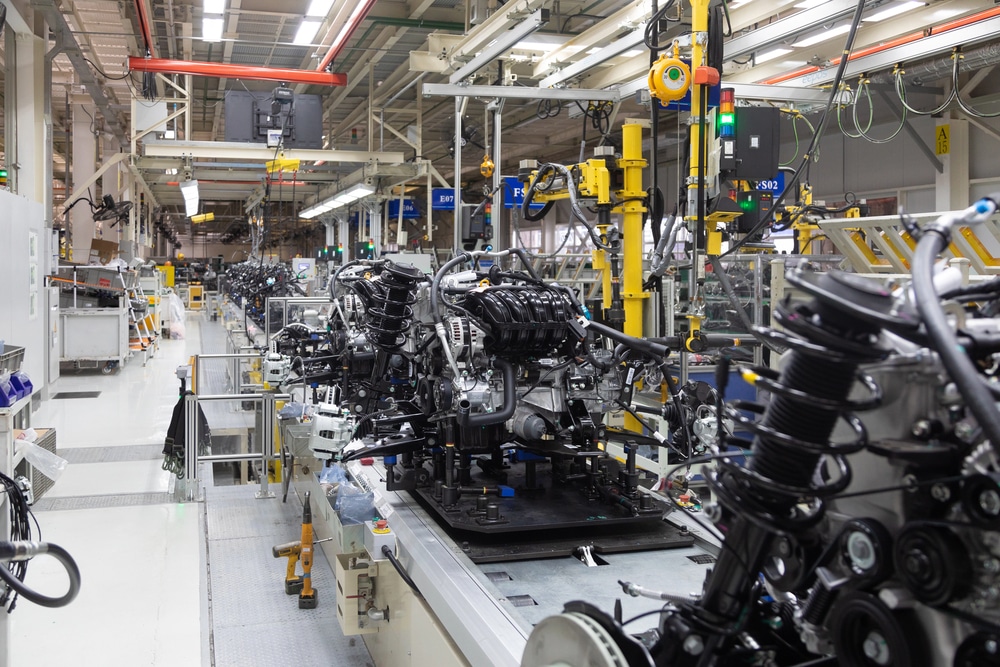

Remanufacturing is the process of restoring used automotive components to a like-new condition. This practice extends the lifecycle of parts such as transmissions and axles, thereby reducing the demand for new production. By adopting remanufacturing, companies not only decrease resource consumption but also align with sustainable manufacturing practices that support the circular economy.

The Growing Importance of Sustainability for OEMs and the Automotive Sector

Original Equipment Manufacturers (OEMs) face increasing pressure to adopt sustainable practices. Both consumers and regulators demand more environmentally responsible solutions. By incorporating remanufacturing into their operations, OEMs can address these demands while also reaping the benefits of cost savings and resource conservation. The automotive sector is experiencing a paradigm shift where sustainability is no longer optional but an essential requirement.

Understanding Remanufacturing: A Circular Solution for OEMs

Disassembling Used Parts

The first step in remanufacturing involves carefully disassembling the used parts. This process requires precision to ensure that all components are separated without causing any additional damage. Proper labeling and storage of each part are essential for efficient reassembly later on.

Cleaning and Inspecting

Once disassembled, each part undergoes thorough cleaning to remove any dirt, grease, or corrosion. Inspection follows, where parts are examined for wear and damage. This step helps identify components that can be reused and those that need further attention.

Replacing or Repairing Components

Components identified as damaged or worn out during inspection are either repaired or replaced. This step is crucial to restore the part’s functionality and ensure that it meets the necessary performance standards.

Reassembling to Original Specifications

After repairs or replacements, the parts are meticulously reassembled to meet the original manufacturing specifications. This ensures that the remanufactured product performs as reliably as a new one. Attention to detail during reassembly is vital to maintain the integrity of the final product.

The Importance of Remanufacturing in the Circular Economy for Automotive Manufacturing

The circular economy promotes a closed-loop system in which products are reused, remanufactured, and recycled instead of discarded. Remanufacturing plays a crucial role in this model by keeping valuable materials in use, thereby significantly reducing waste and environmental impact. In the automotive industry, remanufacturing helps create a sustainable cycle that extends the lifespan of components and decreases the demand for new raw materials.

Environmental Benefits of Remanufacturing for the Automotive Industry

Reduction of Raw Material Use and Waste Generation

One of the most significant environmental benefits of remanufacturing is the drastic reduction in raw material consumption. By reusing existing components, the industry can decrease its reliance on new materials, subsequently reducing the environmental footprint of manufacturing processes. This approach also leads to less waste generation, as fewer parts end up in landfills.

Lower Energy Consumption in Remanufacturing Compared to New Production

Remanufacturing requires substantially less energy than creating new products from scratch. The energy savings arise from the reduced need for raw material extraction and processing. This decrease in energy consumption not only lowers operational costs but also diminishes the manufacturing process’s carbon footprint, aligning with global efforts to combat climate change.

How Remanufacturing Benefits OEMs by Reducing Waste and Extending Product Lifespan

Minimizing Product Waste and Reducing Landfill Use

Remanufacturing plays a crucial role in minimizing product waste and reducing landfill use, particularly in the automotive industry.

Success Stories: Companies Leading the Way

Companies like Dynamic Manufacturing have effectively remanufactured transmissions and other automotive components, which are traditionally resource-intensive to produce. By restoring these components, they significantly reduce waste and conserve valuable resources.

Extending the Lifecycle of Automotive Components

A key goal of remanufacturing is to extend the lifecycle of automotive components. By giving these parts a second life, manufacturers can optimize their value while reducing their environmental footprint.

Aligning with Sustainability and Strengthening Supply Chains

This strategy not only aligns with sustainability objectives but also strengthens the resilience of the supply chain.

Meeting Regulatory and Consumer Demands for Sustainable Practices

How Remanufacturing Aligns with Global Environmental Regulations

- Remanufacturing aligns seamlessly with international environmental regulations.

- Focuses on reducing industrial waste and emissions.

- Incorporating remanufactured parts helps OEMs ensure compliance.

- Enhances sustainability credentials.

Addressing Consumer Demand for Environmentally Responsible Practices

- Consumers are increasingly conscious of the environmental impact of purchases.

- Remanufactured products provide high-quality components with a reduced ecological footprint.

- Meeting consumer demand for sustainability enhances brand loyalty.

- Attracts environmentally conscious customers.

Future of Remanufacturing: Driving Sustainable Innovation in the Automotive Industry

Advances in Remanufacturing for Hybrid and Electric Vehicles

The rise of hybrid and electric vehicles presents new opportunities for remanufacturing. By applying remanufacturing techniques to electric vehicle components, manufacturers can further reduce waste and promote sustainable practices within the industry. This shift represents a significant step toward a more sustainable automotive future.

How Remanufacturing Supports the Industry’s Transition to Sustainable Practices

Remanufacturing is a powerful force for lasting change, driving the automotive industry toward a sustainable future. By embracing this approach, the industry benefits the environment and solidifies its role as a leader in sustainable innovation.

As we progress, sustainability through remanufacturing is essential. It reduces waste, conserves resources, and lessens environmental impact, paving the way for a greener automotive sector. Dynamic Manufacturing proudly supports this and invites you to join us. Whether you’re an auto enthusiast, industry professional, or OEM seeking sustainable solutions, our team is ready to help. Schedule a consultation today to see how we can drive change together.