Comprehensive In-House Validation And Quality Assurance Solutions

Superior Products From Superior Compliance And Testing.

DYNAMIC VALIDATION

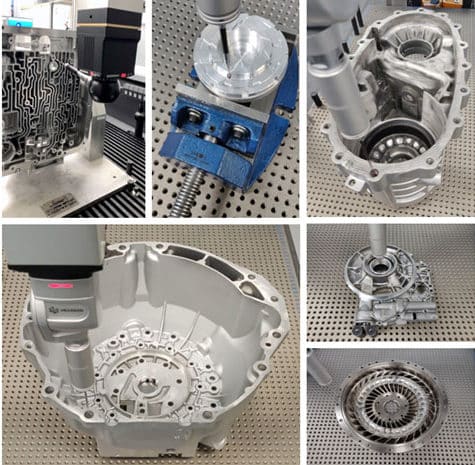

Dynamic Manufacturing operates a full-service quality assurance laboratory at Hillside, Illinois. We’re able to measure and record dimensional data, surface finish, hardness, and insertion/extraction force to validate parts to their exact specifications. With our end-of-life dynamometers, we have the ability to design and construct parts in-house, saving on cost and streamlining efficiency. Partner with Dynamic to leverage our expertise in developing production control plans based on CMM/Vision equipment, custom gauging, and unique end-of-line testing.

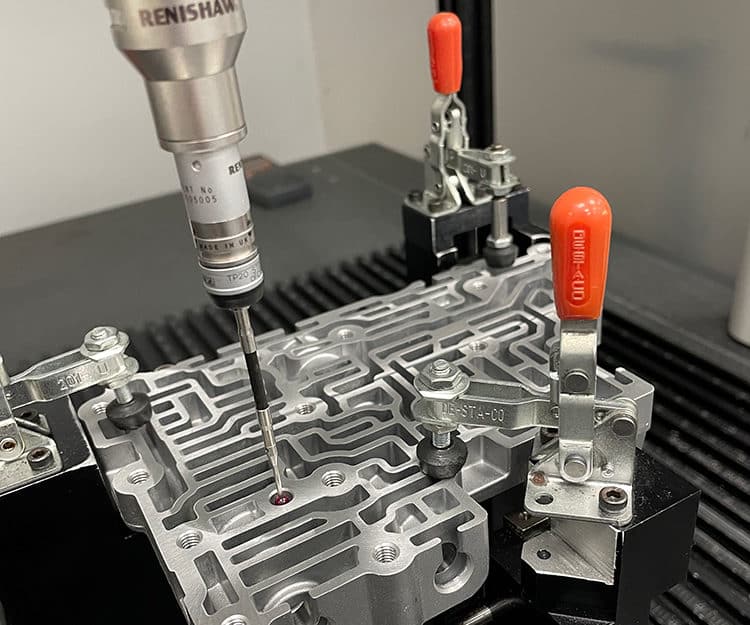

DIMENSIONAL VALIDATION CAPABILITY

HEXAGON CMM GLOBAL S GREEN 7.10.7 CMM

MITUTOYO CMM CRYSTA-APEX S 9108

QVI SPRINT MVP 400 VISION INSPECTION SYSTEM

IN-PROCESS GAUGING

Production parts are monitored by on-going first-piece and in-process inspection. This inspection uses a combination of CMM/Vision Inspection, Air/Linear Variable Differential Transformer (LVDT), Gauging, and Go | No-Go plug gauges as required within the Control plan.

Dynamic expertly leads in the development of:

FAQS

Can you provide customized validation solutions?

Does Dynamic Manufacturing follow industry standards and regulations for validation services?

What is gauging in machining?

WHY DYNAMIC?

IN-HOUSE MACHINING

We make everything for our Customers in-house so we give full assurance in error-free machining, efficient turnaround times, and top-quality performance. Our multiple manufacturing lines provide fully-encompassing turnkey operations for disassembly, machining, fabrication, assembly, and more.

QUALITY COMPLIANCE AND TESTING

Our validation processes strictly adhere to rigorous compliance and testing. Our NoMuda VisualFactory Manufacturing Execution System implements lean principles as a company-wide practice to ensure all machining is completed and validated at the highest level of quality.